Moore International are happy to announce we will be at Machine Building North

Thursday 10th April 2025 at Concorde Conference Centre, Runway Visitor Park, Manchester WA15 8XQ.

Eichenberger Miniature Ballscrews helping to put a smile on peoples faces

Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

Attractive teeth have become synonymous with health, social acceptance and professional success in modern society. Advanced technology can improve and simplify everyday practice, and digitalisation is also progressing rapidly in dentistry and dental technology. Until a few years ago, dental technology remained a field resistant to digitisation and automation. Indeed, the production of individual custom-made parts is not so easy to streamline. However, nowadays, digitalisation is widely used in dentistry on account of the numerous advantages it offers to patients. Today, almost any type of dental laboratory work can be designed on the computer and produced by machine.

Dental technology involves producing all types of dental prostheses, such as dental crowns, bridges and dentures. In the past a dental technician made a plaster model of the teeth using a rubber-like plastic impression, which many patients find uncomfortable. A wax model corresponding to the final prosthesis is then made on this true-to-size tooth stump. By means of different casting processes, the shapes of the wax models can be adopted 1:1 and the dental prostheses produced. The experience of many patients shows that this conventional technique is a very lengthy process.

The computer-aided manufacture of dental prostheses, known as CAD/CAM, not only makes life easier for patients but is also inspiring dentists and technicians alike. It enables digital impressions to be taken of the teeth. It saves time and simplifies the imaging process. When the dentist moves the camera head over the teeth, a detailed 3D image appears on the screen in natural colours. It is possible to rotate the ceramic replacement on the monitor in order to precisely determine the contact points to adjacent teeth, which are also digitally recorded. The high precision of this digital data enables the dentist to design an accurately fitting and high-quality ceramic dental prosthesis. The revolutionary 5-axis scanner with robotic arm and innovative model positioning goes one step further. The unique operating concept allows scanning in fully automatic mode as well as manually in an incredibly short period of time. Impressions, partial and full jaw models can be scanned in less than one minute. Similarly, the 5-axis scanner is able to scan the roof of the mouth, enabling digital design of model castings.

A slightly adapted version of Eichenberger’s Carry 4x1 ball screw has all the capabilities needed to allow this new type of positioning scanner to achieve groundbreaking efficiency and flexibility of movement. Special software calculates what the healthy tooth once looked like in that position. The digital data set is then sent to a milling machine, generally located in an adjoining room. A high-quality, metal-free and precise dental prosthesis is then produced in just one session.

Small, precise and suitable for cleanrooms are key requirements, especially in the medical sector. The Carry cold-rolled miniature ball screw is the answer and now successfully occupies this market niche, offering an alternative to the high-priced milled spindles of miniature alternatives.

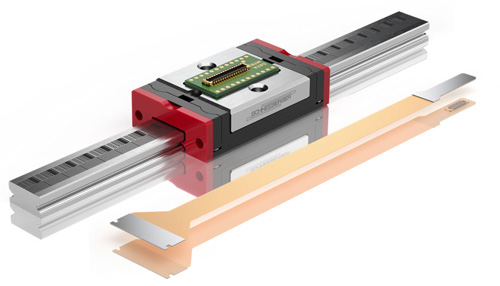

Introducing SAM the new SCHNEEBERGER absolute measuring system

Precision in a Small Space – The SCHNEEBERGER Absolute Measuring System SAM sets new standards in industry.. Ideal for high-precision applications in mechanical engineering and medical technology.

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

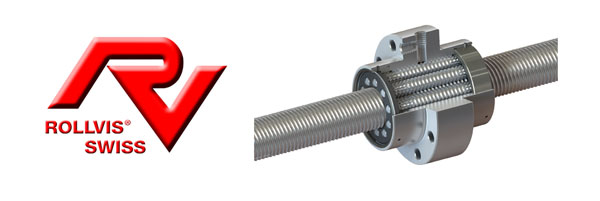

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

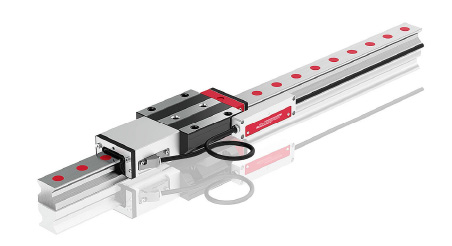

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?

Ballscrews & Leadscrews are among the most frequently used drive systems in many areas. The Eichenberger spindle technology and thread rolling (cold forming of outer surface of round parts) combine maximum load-bearing capacity and force density with incredible dynamics, amazing precision and maximum running performance.