Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

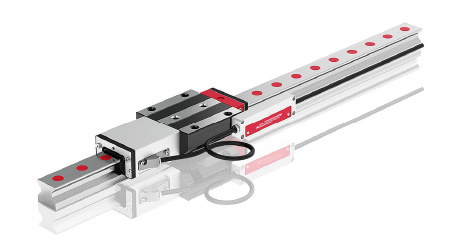

Linear rail integrated measuring system from Schneeberger

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. This can be a time consuming and costly process when working out which measuring system will work best with the carriage and rail within the machine. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

The Schneeberger AMS integrates a measuring head and scale onto its Monorail profile linear guideways. The Integrated AMS distance measuring systems are machine-compatible, ready-to-install and suitable for a wide range of applications in mechanical engineering and automation.

The major advantage of the Monorail AMS distance measuring system is that by integrating the measuring system into the Monorail carriage and applying the measuring scale to the guideway, it is possible to save space and reduce the overall installation process within complex machine designs. The use of Monorail AMS is economical without having to compromise on performance.

Whenever incorporating a measuring system into a machine design, there is the risk of contaminating the measuring scale due to harsh environments. This can greatly impact the functionality of the entire machine, as often can be the case when using external optical or magnetic measuring systems. Because AMS is incorporated into the carriage and therefore protected from the elements, this risk is significantly reduced.

Schneeberger Monorail carriages are equipped as standard with twin-lipped cross wipers on the ends and top and bottom longitudinal wipers. Together with additional sealing of the gaps between the front plate and the steel body, these provide an exceptionally efficient sealing system. The ingress of dirt is therefore effectively prevented and lubrication losses are reduced to a minimum, which results in a significant increase in service life and long-lasting reliability!

The maximum one-piece profile rail length for all AMS distance measuring systems is 6 meters. For the analogue systems, however, several Monorail guideways can be combined as required. Thanks to the special design of the rail joints, in combination with the AMSA 3L read head, joints can be traversed, and any lengths of measuring axes can be constructed.

If you would like to know more about Schneebergers AMS systems contact

Moore International,

Unit 6 Factory Road,

Upton Industrial Estate,

Poole,

Dorset

BH16 5SL

01202623393

www.mooreinternatioal.co.uk

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?

Ballscrews & Leadscrews are among the most frequently used drive systems in many areas. The Eichenberger spindle technology and thread rolling (cold forming of outer surface of round parts) combine maximum load-bearing capacity and force density with incredible dynamics, amazing precision and maximum running performance.

Moore International prides itself on ensuring precision from start to finish. Please take the time to watch this short overview video of what we are all about.

Moore international will be hosting a stand at this years Machine Building Live on the 4th October 2023. The venue is the National Motorcycle Museum in Birmingham located immediately adjacent to the NEC B920EJ.