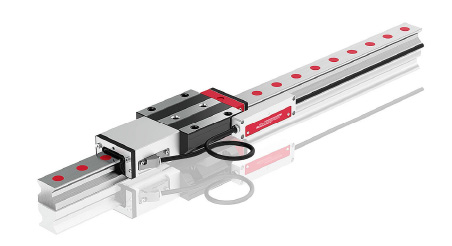

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

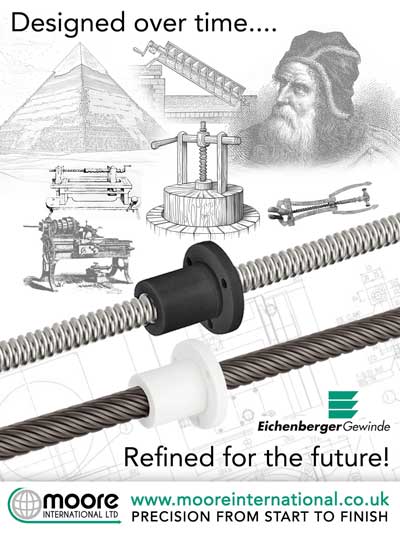

Eichenberger Ballscrews cold rolled excellence!

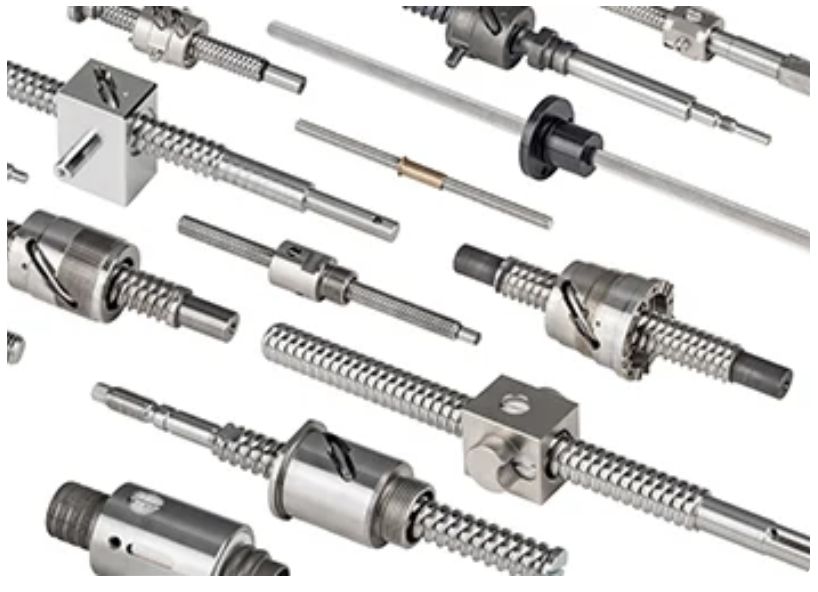

Design engineers regularly have to determine the most suitable drive solution for implementing linear movements. Today's forever advancing technological progress in machine building and automation has resulted in increased complexity. Ballscrews and leadscrews are among the most frequently used drive systems in many areas. Rolled thread screws have become established in the linear sector as cold-formed spindles result in highly efficient drive systems with the additional clear advantage of excellent energy efficiency

Reliability and customer benefit are no coincidence

The Eichenberger spindle technology and thread rolling (cold forming of outer surface of round parts) combine maximum load-bearing capacity and force density with incredible dynamics, amazing precision and maximum running performance.

Despite the big differences between the various fields of application, Eichenberger Ballscrews and Leadscrews can be found in the following industries

Industrial automation

Electrical and automotive engineering

Robotic engineering

Medical technology

Satellite technology

Space exploration

Semiconductors research

Photovoltaic systems

Vacuum valves

The similarity in requirement here are high precision, higher intelligence, superior performance and the search for economical overall solutions.

What makes the Eichenberger cold rolled screws such a resilient and ideal functional element?

Thread rolling produces very precise geometries with high surface quality. Typical thread manufacturing processes such as milling, turning or whirling involve machine cutting the material, with the disadvantage of interrupting the grain of the steel. However, thread rolling diverts the longitudinal fibres rather than using cutting and the surface profile hardens at the same time. This "smooth rolled surface" offers little opportunity for dirt to attack. This is crucial for a long service life and also decisive for the quiet rolling of the balls. Cold forming also results in very good roughness values (~ Rz 1.0) on the thread flanks and in the base radius.

A radial dynamic force is exerted

between two rotating rolling dies to form the thread.

Always in focus: Efficient, coste ffective overall solution for customers

Choosing the correct drive technology has many variables to consider. Time and cost pressures combined with objectives such as precise processes, high load capacities and speeds together with service life. Over the decades, Eichenberger has produced and developed an impressive selection of ball and leadscrew drives. Designers at Eichenberger always try to build on an existing product and adapt the screw drive to the specific applications requirements. This results in a decisive price advantage, making the product more competitive for the customer.

Moore International can supply you with off-the-shelf or in-house custom machined ballscrews and leadscrews made to your requirements. By chosing Eichenberger you can be sure of precision from start to finish.

Talk to us today about your Ballscrew and Leadscrew requirements.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

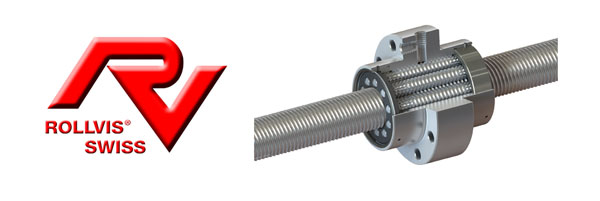

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?

Moore International prides itself on ensuring precision from start to finish. Please take the time to watch this short overview video of what we are all about.

Moore international will be hosting a stand at this years Machine Building Live on the 4th October 2023. The venue is the National Motorcycle Museum in Birmingham located immediately adjacent to the NEC B920EJ.

Moore International’s ever-expanding CNC machining and turning facilities have become the heart of what makes the company a premium supplier of bespoke quality leadscrews and ballscrews.