Moore International are happy to announce we will be at Machine Building North

Thursday 10th April 2025 at Concorde Conference Centre, Runway Visitor Park, Manchester WA15 8XQ.

New machining capabilities for your custom ballscrews and leadscrews

Moore International’s ever-expanding CNC machining and turning facilities have become the heart of what makes the company a premium supplier of bespoke quality leadscrews and ballscrews.

The facility now hosts numerous CNC machining centres including high-specification 5 axis CNC mills and CNC driven tool lathes with high-volume bar feeders and Inductelec induction metal softners. This gives Moore International considerable machining capabilities which they can apply to their range of custom high-quality linear motion products.

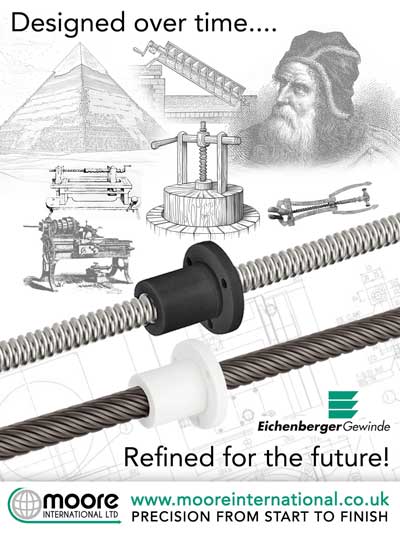

Based in Poole, Dorset, Moore International have been supplying custom Swiss precision ballscrews and leadscrews from Eichenberger Gewinde to the industry for many years. The Eichenberger range of ballscrews and leadscrews has been a popular choice where precision and quality of materials and manufacture are key to the customer’s design.

Whether it's speed, weight or cost-efficiency, Eichenberger have leadcrews to fit most requirements. Eichenberger Speedy high-helix leadscrews give unprecedented high-travel speeds from very low rotational speeds. Their Rondo round-thread leadscrews give high levels of efficiency with extremely low noise levels - an ideal alternative to conventional trapezoidal leadscrews. Eichenberger Easy, lightweight rolled aluminum leadscrews with a friction-resistant coating (hard anodised) are ideal for increased loads in challenging climatic conditions or difficult environments.

The Eichenberger Ballscrew range includes no-wear ballscrew drives, ideal for moving heavy loads with low energy consumption. Their cold-formed screws that stand out for their robustness, precision, strength, efficiency and smooth-running. This form allows for extreme pitches, giving unprecedented travel speeds. The nuts are fitted with various ball returns, fully integrated into the nut body. The optimum system for your drive solution is selected on the basis of dimensions, temperature, travel speed, load and application range,

Custom screw end-journal machining

The in-house CNC facilities mean that end-journal machining can be applied to all of the types of screws Moore International supply regardless of diameter and type. The highly skilled in-house machinists can work directly from drawings, CAD files or from a sample to copy.

Custom leadscrew nuts

Offering a complete custom nut manufacturing facility for any of their leadscrews, gives the freedom to design a nut around the product and not the product around a nut

Custom CNC machined parts

Moore International offers other bespoke CNC part manufacturing and includes a dedicated assembly team. The team can assemble a collection of parts to any required specification, at the highest level of quality and deliver them to you with your part number attached for easy traceability.

With many other linear motion products and over 40 years in the industry, find out today what Moore international can do for you.

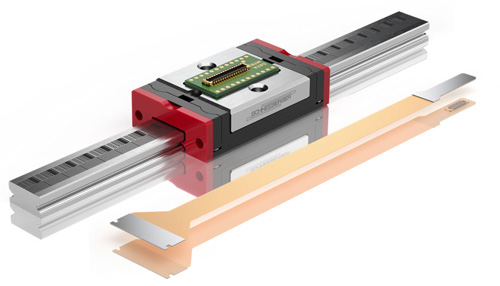

Introducing SAM the new SCHNEEBERGER absolute measuring system

Precision in a Small Space – The SCHNEEBERGER Absolute Measuring System SAM sets new standards in Industry 4.0. Ideal for high-precision applications in mechanical engineering and medical technology.

Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

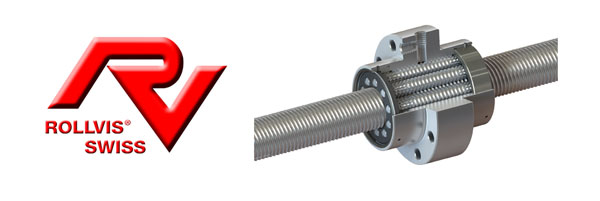

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

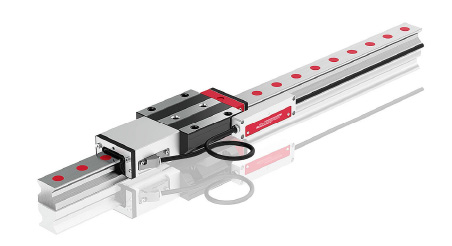

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?