Moore International are happy to announce we will be at Machine Building North

Thursday 10th April 2025 at Concorde Conference Centre, Runway Visitor Park, Manchester WA15 8XQ.

Is Roller Screw technology still underappreciated ?

Is Roller Screw technology still underappreciated ?

Mark Moore of Moore International Ltd explains their advantages

Even though the very first patent for a satellite roller screw was granted in 1949, why is roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?

When designers consider the options for controlled linear motion, do they fully examine the benefits that the roller screw offers in performance in relation to hydraulic or pneumatic cylinders, as well as ball or lead screws ? Satellite roller screws have distinct advantages over these four other rivals in all of major selection considerations. Of course, each designer may have differing selection criteria, which will be determined by the application.

So, in examining the major selection concerns, here is how the roller screw performs ...

If we take efficiency as primary criterion for selection, the roller screw is over 90% efficient, and only the ball screw out of the five recognised choices can compare. Life expectancy is very long for a roller screw, typically 15 times longer than a ball screw, and only the hydraulic or pneumatic cylinder options give similar service life, however, they both need maintenance to retain long life.

When it comes to maintenance itself, the roller screw requires very little maintenance as the friction created by the rolling screw design is minimal compared to that generated by sliding friction. However, the roller screw should still be lubricated to minimise wear and to dissipate heat. Providing sufficient protection against contaminants is also critical to long functional life, so wipers can be added to the front or back of the nut to scrape particulates from the threads throughout the screw stroke. Maintenance intervals will depend on two main factors, the operating conditions and the screw diameter. By comparison, both hydraulic and pneumatic cylinders need much higher levels of attention, and ball screws can suffer from pitting in the ball groove and the ball bearings can be lost or need replacing.

The load ratings of a satellite roller screw can only be matched by a hydraulic cylinder. In performance, roller screws have, in some specific applications, been able to move up to 20,000 times its own weight, so are capable of carrying greater loads in relation to their size. They are also very suitable to carry heavy loads for continuous duty and in the most arduous of conditions. The combination of speed and acceleration can only be equalled by that of a pneumatic cylinder. Both the stiffness and the effects of shock loading also make the roller screw an attractive option.

Automated industrial production lines are being designed to be more compact systems that take up less space. One of the biggest advantages of the roller screw is that it requires only minimal space requirement as it is very much more compact and is much easier to install than hydraulic or pneumatic cylinder alternatives, both of which can be very complex and expensive to fit. At the same time the roller screw achieves considerably better positional accuracycompared with a ball screw.

Environmentally the roller screw is less noisy in operation, which compares well to pneumatic systems, but also has the obvious advantages of leak free functionality (air and hydraulic fluid) and less power consumption.

The return on investment by purchasing satellite roller screw technology is offset through total cost of ownership and life cycle costs. It is realised through the reduction in the cost of maintenance, early replacement and resulting downtime.

.

How do roller screws function and what are the options ?

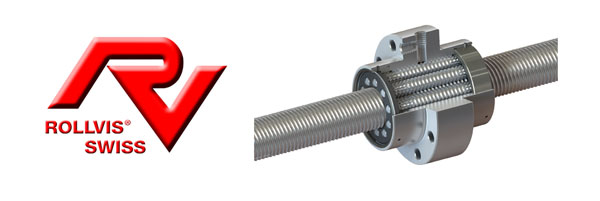

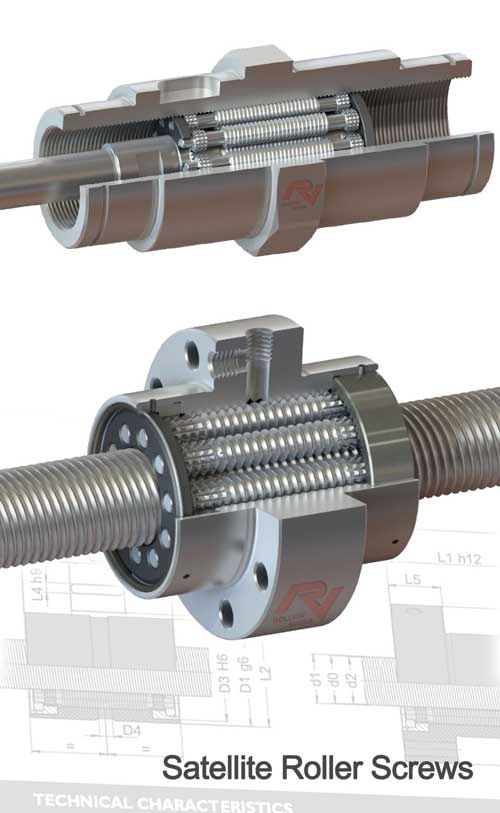

Roller screws use rollers to transmit force from the nut to the shaft. The main elements are the screw, the nut and the satellite rollers. Moore International supply the ROLLVIS Swiss range of roller screws which are used to transform rotary movements into linear movements and vice versa. The rolling elements are threaded rollers between the screw and the nut. The high number of points of contact enables satellite roller screws to support very heavy loads.

The ROLLVIS range comprises satellite roller screws with no recirculation (RV and HRV types), inverted roller screws (RVI type), Differential roller screws (RVD type) and screws with recirculating rollers (RVR type). Bearing units are also proposed to equip the different roller screw designs.

The RV screw is a high precision, robust assembly where the rollers do not recirculate, thus enabling a very stable driving torque. Special gears are designed on the rollers and nut to maintain a good kinematics even in the most severe conditions. The internal thread of the nut is identical to that of the screw. To ensure no axial movement occurs between the nut and the rollers, there is a single-start thread with precise angle accuracy between the nut and the rollers.

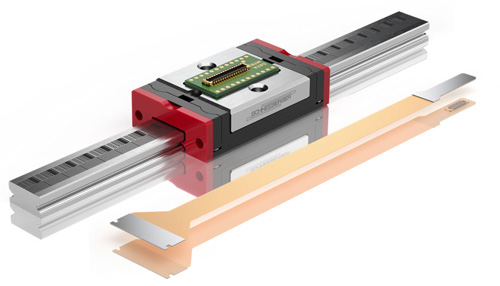

Introducing SAM the new SCHNEEBERGER absolute measuring system

Precision in a Small Space – The SCHNEEBERGER Absolute Measuring System SAM sets new standards in Industry 4.0. Ideal for high-precision applications in mechanical engineering and medical technology.

Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

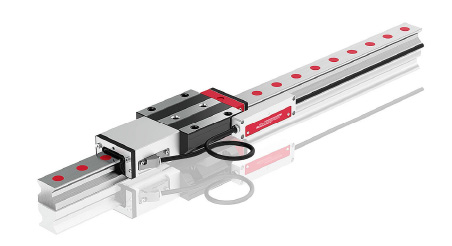

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

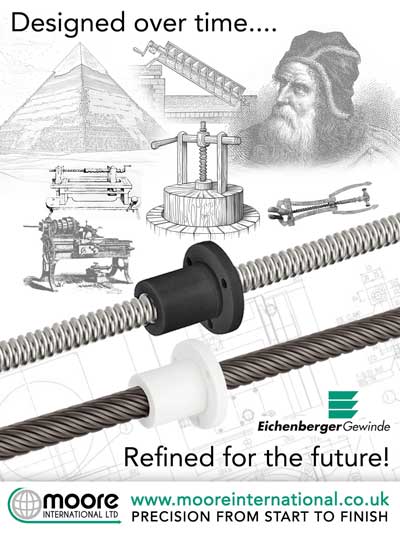

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Ballscrews & Leadscrews are among the most frequently used drive systems in many areas. The Eichenberger spindle technology and thread rolling (cold forming of outer surface of round parts) combine maximum load-bearing capacity and force density with incredible dynamics, amazing precision and maximum running performance.