Moore International are happy to announce we will be at Machine Building North

Thursday 10th April 2025 at Concorde Conference Centre, Runway Visitor Park, Manchester WA15 8XQ.

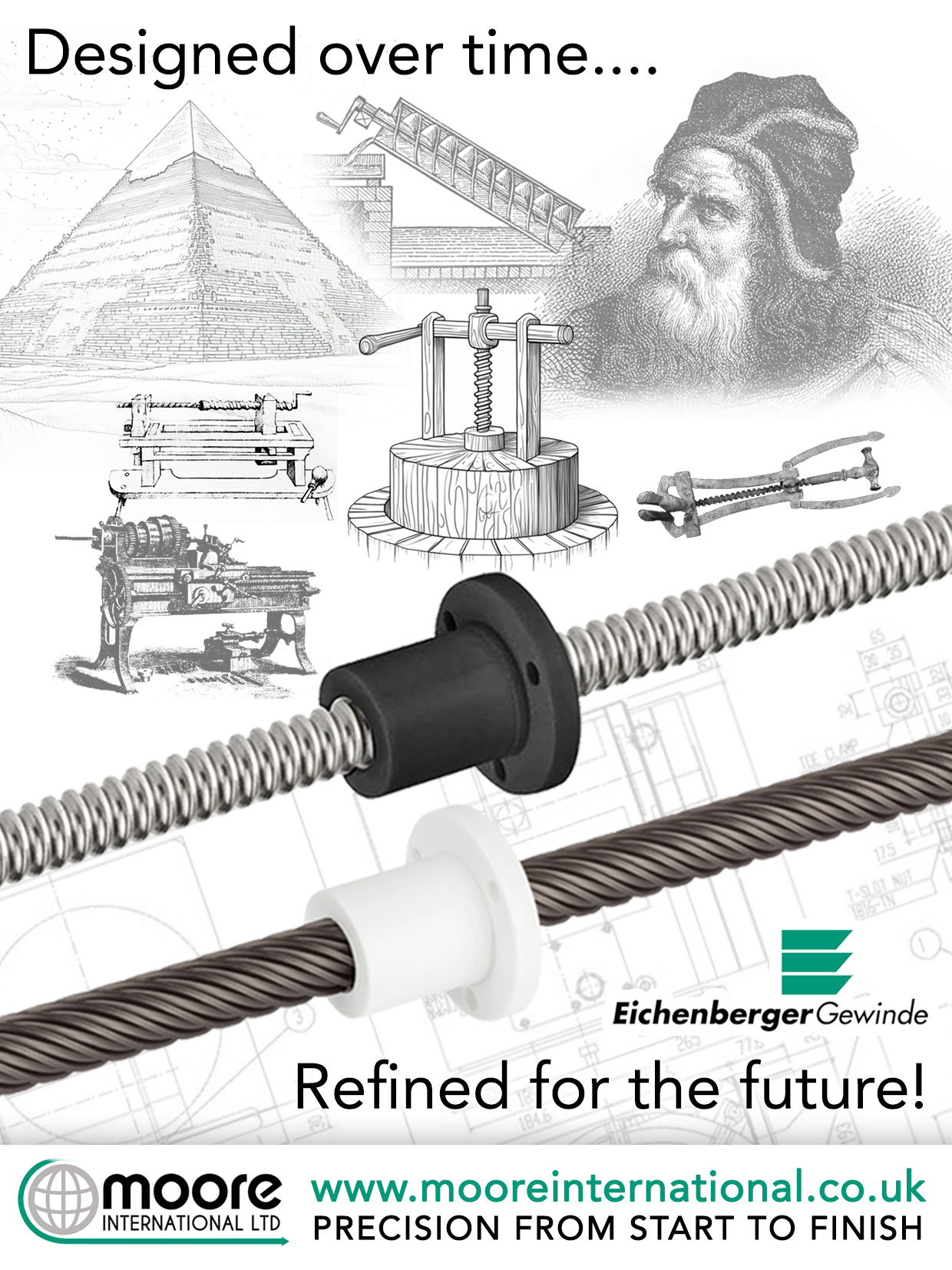

Who invented the Leadscrew?

Leadscrew: A screw used as a linkage in a machine, to translate turning motion into linear motion

Screw technology can be found throughout history in many forms. But where are its origins? Early examples can be seen in the olive oil and wine presses of ancient Greece. Roman history books also show examples of screw technology being used in simple screw fasteners and early surgical instruments. The Greek mathematician Archimedes is usually credited to the invention of the screw around 240BC with the design of the ‘Archimedes screw water pump’. It is often disputed that this design seems to of been borrowed from the even earlier times of ancient Egypt. It is safe to say that the knowledge of turning rotary motion to linear motion with the use of a screw has been known for a very, very long time! From these early examples millennia’s ago there was very little development in screw technology, until the Renaissance period of the 15th century. Leonardo da Vinci’si (1452-1519) works contain descriptions of tools for cutting thread and extensive designs for various moving & fastening screws that are still in existence today. Followed by the Industrial revolution in the 16th century, where screws were being manufactured in factories allowing cheaper faster production and wider use. By the 18th Century in Europe, screws were manufactured and cut on mass using lathes. The lathes used cutting tools mounted on a nut moving along a threaded shaft. This is an early example of Leadscrews being used in a similar way to how they are used today.

Nowadays, leadscrews can be found everywhere in modern technology such as printers, scanners, CNC machines, robots, automated laboratory equipment, lifts and many other applications. Utilizing this simple idea of rotary motion to linear motion, Leadscrews give quick, efficient, accurate and precise linear motion control with small to large lifting capacities. The biggest change in leadscrew technology over the years is in how the thread itself is formed.

Moore International have been in the linear motion industry for over 30 years and have supplied thousands of metres of precision lead screws all around the world. They are the UK distributor and supplier of Swiss manufacturer Eichenberger Gewinde’s Leadscrews and Ballscrews. Eichenberger leadscrew and nut have become the industry standard in quality high-precision leadscrews. What sets them apart is the way their screw is produced using their cold-rolled thread forming process.

Mark Moore CEO of Moore International explains why Eichenberger cold-formed spindles have clear advantages.

“Typical leadscrew thread manufacturing processes such as milling, turning or whirling involve machines cutting the material, with the disadvantage of interrupting the grain of the steel. However Eichenberger’s cold-rolling produces very precise thread geometries with high surface quality. Instead of cutting, a radial dynamic force is exerted onto the shaft between two rotating rolling dies to form the thread. Thread-rolling diverts the longitudinal grain of the metal, hardening the surface profile at the same time. This "smooth rolled surface" offers little opportunity for dirt to attach aiding in low friction, low noise, long service life and giving excellent energy efficiency of the screw”

Forever advancing technological progress in machine building and automation has resulted in increased complexity for design engineers. Leadscrews are among the most frequently used drive systems in many areas due to their simplicity and reliability. Using Eichneberger’s range of leadscrews give a wider choice of possibilities to designers. Eichenberger’s cold-rolled threaded shafts give them clear performance advantages in any situation. The Eichenberger range includes

SPEEDY. Eichenberger Speedy high-helix leadscrews give unprecedented high travel speeds from very low rotational speeds

RONDO. Eichenberger Rondo round-thread leadscrews give high levels of efficiency with extremely low noise levels. An ideal alternative to conventional trapezoidal leadscrews.

EASY. Eichenberger Easy, lightweight rolled aluminium leadscrews with a friction-resistant coating (hard anodised). Ideal for increased loads in challenging climatic conditions or difficult environments.

All can be combined with a choice of nut material and optional low friction and protective coatings.

Moore International can supply off-the-shelf or in-house custom CNC machined leadscrews made to your requirements and by choosing Eichenberger leadscrews you can be sure of precision from start to finish.

Although it’s unclear whether it was the Greeks or Egyptians that are responsible for the discovery of screw technology leading to the invention of the leadscrew, we can definitely say it is Eichenberger that have refined it for the future!

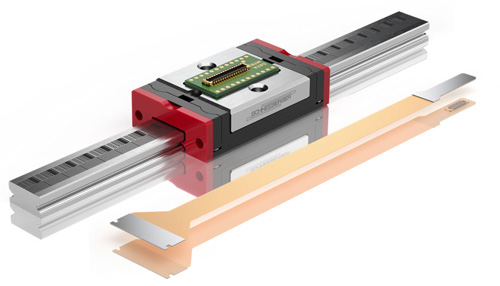

Introducing SAM the new SCHNEEBERGER absolute measuring system

Precision in a Small Space – The SCHNEEBERGER Absolute Measuring System SAM sets new standards in Industry 4.0. Ideal for high-precision applications in mechanical engineering and medical technology.

Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

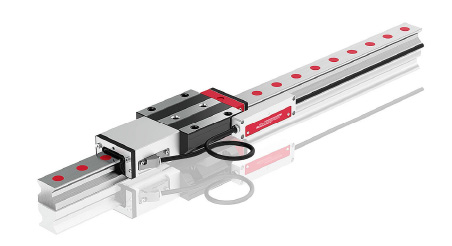

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

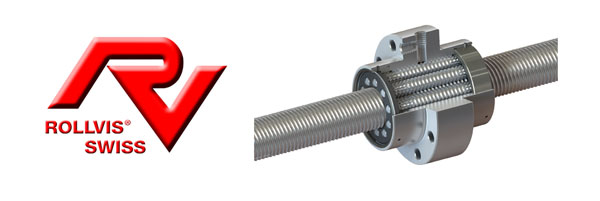

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?

Ballscrews & Leadscrews are among the most frequently used drive systems in many areas. The Eichenberger spindle technology and thread rolling (cold forming of outer surface of round parts) combine maximum load-bearing capacity and force density with incredible dynamics, amazing precision and maximum running performance.