Moore International are happy to announce we will be at Machine Building North

Thursday 10th April 2025 at Concorde Conference Centre, Runway Visitor Park, Manchester WA15 8XQ.

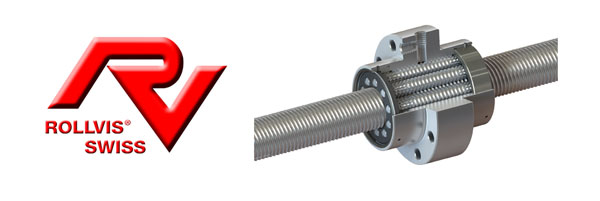

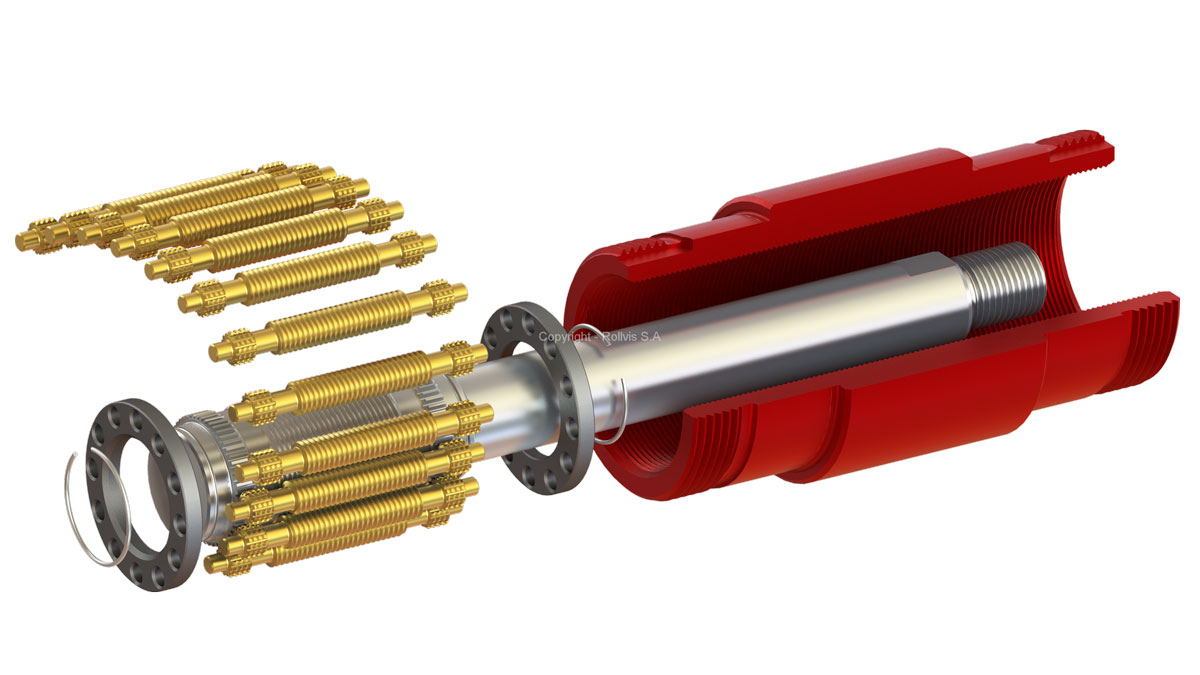

Rollvis Swiss satellite rollerscrews - a superior linear drive alternative

| |

| Satellite rollerscrews are similar to ballscrews, but with one important difference: the load transfer elements are threaded rollers instead of balls. The rollers offer a large number of contact points to transfer the load. They can achieve over 90% efficiency and have an expected life up to 15 times longer than any ballscrew equivalent. Rollerscrews are capable of very heavy load capacities and high acceleration and deceleration speeds, making them a superior linear drive alternative. | |

| |

| |

| Call us for more information on Rollvis satellite rollerscrews. Visit our online Rollvis section here |

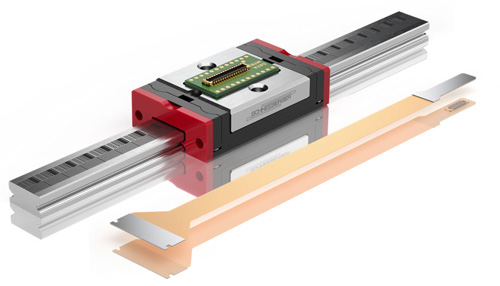

Introducing SAM the new SCHNEEBERGER absolute measuring system

Precision in a Small Space – The SCHNEEBERGER Absolute Measuring System SAM sets new standards in Industry 4.0. Ideal for high-precision applications in mechanical engineering and medical technology.

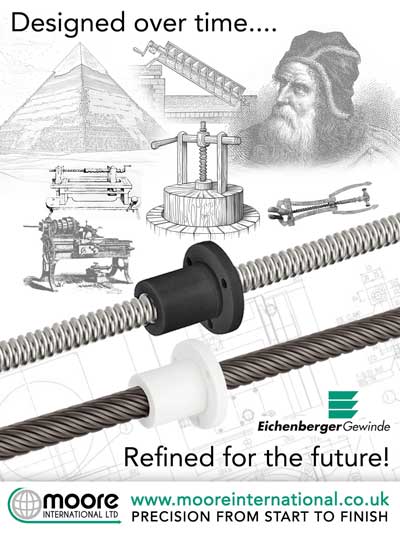

Eichenberger develops, designs and manufactures ultra-small, high-precision ballscrews that are often utilised in the sensitive and demanding applications of the biotech, pharmaceutical and medical technology industries. Eichenberger’s cold-rolled, hard and smooth thread surfaces make them ideal for applications in sterile and clean environments.

Here’s how an Eichenberger ballscrew just 4mm wide and with a pitch of 1mm is helping to put a smile on people’s faces around the world.

Machine designers looking to apply precise distant measuring systems to linear carriages and rails have always had to consider the design, fit, compatibility and reliability of the extra hardware involved. When space constraints and performance are key to design requirements Schneebergers ‘Monorail AMS’ is the answer.

Come and see us at stand 105 at this years Machine Building Live at the National Motorcycle Museum in Birmingham.

A great opportunity that will allow attendees the unique chance to meet the experts face-to-face.

Worldwide, there are a total of four large latest-generation Cherenkov telescopes: Australia, Namibia, La Palma and the USA. Around 4000 electrically driven, cold-rolled ballscrews help researchers to observe the cosmos from the Canary Island and to gain more knowledge about mysterious objects and extreme events in the universe. Positioning the telescopes in the northern and southern hemispheres allows for optimal monitoring. Just what exactly do these observations accomplish and how does Eichenberger Gewinde AG play a role in such valuable findings?

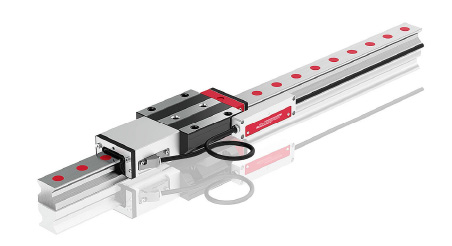

Rollvis satellite rollerscrews (also known as planetary rollerscrews) a linear motion solution with enhanced reliability and performance

We have just updated our prices forSchneeberger's Monorail BM series linear rails and carriages. This gives a massive saving on the whole BM range with prices reduced by up to 40%

Leadscrew technology can be found throughout history in many forms. But where are its origins?

Why is satellite roller screw technology a less recognised option, when compared to other mechanisms for conversion of rotary torque into linear motion ?